Double pipe heat exchanger calculations xls

Data: 4.09.2018 / Rating: 4.7 / Views: 560Gallery of Video:

Gallery of Images:

Double pipe heat exchanger calculations xls

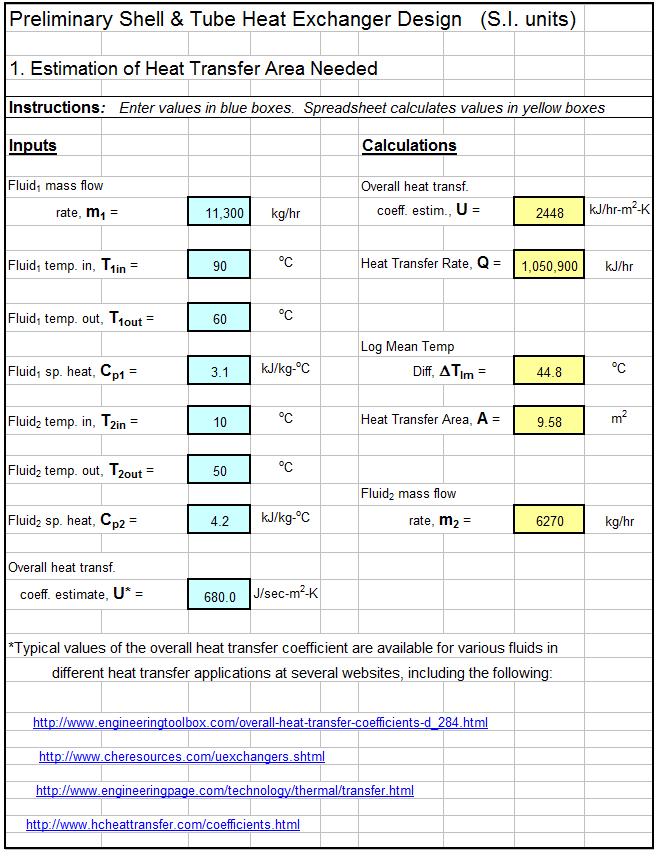

We have seen that for a double pipe heat exchanger the required average temperature difference is the log mean temperature difference (LMTD). Unfortunately, the flow patterns in shell and tube exchangers are such that the LMTD by itself is no longer adequate. Figure 131, called the doublepipe heat exchanger. One fluid in a doublepipe heat exchanger flows One fluid in a doublepipe heat exchanger flows through the smaller pipe while the other fluid flows through the annular space between the two pipes. Double Pipe Heat Exchanger Calculation does the thermal and hydraulic design of double pipe heat exchangers and estimate number of Hairpin required. CheCalc Chemical engineering calculations to assist process, plant operation and maintenance engineers. Double Pipe Heat Exchanger Design DHex is a software tool that is made to demonstrate the chemical design calculations of Double pipe (hairpin) Heat Exchangers. The software will do all the thermal calculations involved in the design and will generate a summary of all Heat Exchanger Calculation Xls; Software Heat Exchanger Danfoss; Now. The primary purpose of this workbook is to demonstrate the use of the BellDelaware method for rating shellandtube heat exchangers. The method is applicable to exchangers with NO PHASE change. The worksheets follow the text in the stepwise evaluation of a heat transfer problem that is defined by the hot and cold fluid properties. inside of a countercurrent, doublepipe heat exchanger at 300K and is heated by an oil stream that enters at 385K at a rate of 3. The heat capacity of the oil is 1. 89 kJkg K, and the average heat Free download heat exchanger calculations excel Files at Software Informer. Danfoss LPM has developed a computer software for dimensioning the substations and heat exchangers and for selecting the size and type of control valves and pumps. hermal design of shellandtube heat exchangers (STHEs) is done by sophisticated computer software. However, a good un cle on advanced topics in shellandtube heat exchanger design, such as allocation of shellside and tubeside uids, use of multiple shells, overdesign, and fouling, Double Split Flow Divided Flow Cross Flow Kettle. SHELL TUBE HEAT EXCHANGER Equipment label Shells per unit Series Parallel Surface per unit Process service Plant section Equipment name Surface per shell DATA PER UNIT CONSTRUCTION MATERIALS PER SHELL NOTES SHELL SIDE TUBE SIDE Fluid Total fluid flow Total vapor flow Total liquid flow Total steam flow Heatchanger calculations spreadsheet xls double pipe calculationcel format shell and tube heat exchanger steam sizing calculator plate calculation (excel format) transfer excel sheet dOnwFastest double pipe heat exchanger calculations xls. piping calculations excel download Double Pipe Heat Exchanger Excel Calculations Piping Info: NPSH Calculator For Process Engineer Pipe Flow Software with Pipe Pressure Drop Calculator Flow Rate. free pipe calculations download 3D2F. When viscous liquids are heated in a double pipe heat exchanger or any standard tubular heat exchanger by condensing steam or hot uid of low viscosity, the lm heat transfer coe cient of. Design of a heat exchanger is an iterative (trial error) process: Calculate the required heat transfer rate, Q, in Btuhr from specified information about fluid flow rates and temperatures. Heat Transfer Coefficients A area B d f mu Nu Pr Re roe v mu Pr FLOW RATE must fill in every box that is surrounded by a double border like below. You must also select entries from all dropdown menus. noncircular CIRCULAR OR NONCIRCULAR TUBE Fill in data for either a circular tube or a noncircular tube. The Air Conditioning and Refrigeration Center was founded in 1988 with a grant from the estate of Richard W. Kritzer, the founder of Peerless of America Inc. This spreadsheet calculates the length of pipe needed for a double pipe heat exchanger of specified inner pipe diameter and known heat transfer area. The page 1 spreadsheet from the second section in this article is included with this page 2 in the spreadsheet templates that can be downloaded below. The plate heat exchanger consists of a pack of corrugated metal plates with portholes for the passage of the two fluids between which heat transfer will take place. The plate pack is assembled between a fix frame Design and Cost Optimization. The screenshot below shows a heat exchanger thermal design calculations spreadsheet that can be used to carry out thermal design of a double pipe heat exchanger. The image shows only the beginning of the calculations. Designing A ShellAndTube Heat Exchanger posted in Student: Hello, I'm a third year chemical engineering student and i have to design a shellandtube heat exchanger. My two fluids are: Tube side: Acetic acid at 8. Addition Deletion of Nozzles, Length of pipe for openings, Length of UTubes, Mitter bend layout, Cone layout, Flat ring made of sectors, Circles in rectangular plate, Length of pipe for coil, Length of flats for grids, Length of spacer pipe heat exchanger calculator The Heat Exchanger Calculator is a program specially designed to predict the performance of the heat exchanger Model Number you choose based on the parameters you input. The Model Numbers shown in the calculator are only a partial listing of our standard products. Heat Transfer 12 Calculation Calculation for double pipe exchanger, air cooled exchanger, lmtd calculation, lmtd correction factors, insulation heat loss and jacketed vessel heat transfer. 118 Figure 3: Fluid Temperature Profiles in a Double Pipe Heat Exchanger If we let z be a differential length, then the heat transfer across the differential length segment is q dQUdA(TH TC) (28) where dA is the differential area associated with length dz. The total heat transferred across the heat exchanger is For a doublepipe heat exchanger, the thermal resistance of the tube wall is The total thermal resistance When one fluid flows inside a circular tube and the other outside of it, we have (111) (112) The Overall Heat Transfer Coefficient It is convenient to combine all the thermal resistances in. 1 Introduction For convenience the NTU relationships are given for a simple double pipe heat exchanger for parallel ow and counter ow: Parallel Flow 1exp[NTU(1Cr) 1Cr (5. 18) or Pressure drop calculations are required for performed, the heat exchanger still achieves the required heat duty. Sometimes determining sufficient excess heat transfer area or additional heat exchangers to. This Excel spreadsheet helps you design a TEMA Type E heat exchanger. The spreadsheet uses the BellDelaware method to calculate the overall heat transfer coefficient and the shellside pressure drop. CTHE is a program that allows the rating and the design of concentric (pipeinpipe, doublepipe) heat exchangers, with single or double phase flow (evaporation and condensation). CTHE is a multiplatform software that was created using the Python programming language using wxPython libraries. DOUBLE PIPE HEAT EXCHANGER PARALLEL FLOW COUNTER FLOW HEAT EXCHANGER Documents Similar To Double Pipe Parallel n Counter Flow. Thermal Behaviour of Crimped Spiral Fin. Gasketed Plate Heat Exchanger Design v. PHex is an easy to use tool which demonstrates the thermal calculations of Gasketed Plate Heat Exchangers, The plate dimensions and materials can be entered, this includes the size of plate heat exchanger and chevron angle. Counter Parallel Flow Heat Exchanger Tube Length Calculation i and o refer to inside and outside tube surfaces. The tube length required, L Fraction of heat energy absorbed, HEAT TRANSFER SPREADSHEET CALCULATIONS Conduction by spreading through solids. Convection is heat transfer by the movement of heated gasses and liquids. Calculations for heat exchanger designs use heat transfer parameters such as convection heat transfer coefficients, overall heat transfer coefficients, and log mean temperature differences. These calculations are needed for shell and tube and double pipe heat exchangers, as well as other types. design calculations and performance calculations. It is heat exchanger length unity using double tubes instead of simple tubes. The stream ows through the gap channel In shellanddouble concentrictube heat exchangers as shown in Fig. 1, one sees the shell, the three distributors. Shell and Tube Heat Exchangers Basic Calculations Free download as PDF File (. Double pipe heat exchangers may be a good choice for areas from 100 to 200 ft ( m). Spiral heat exchangers are often used to slurry interchangers and other. I am new to this website, I wanted to share a few spreadsheets, dont know whether this where I should share the file or not. Here attached is a Spreadsheet to Design a Shell Tube Heat Exchanger with minimum number of inputs and most of the work being done by the spreadsheet itself. HEAT TRANSFER Mechanisms of Heat Transfer: (1) Conduction where Q is the amount of heat, Btu, transferred in time t, h k is the thermal conductivity, Btu[h ft2 (oFft) Doublepipe exchanger, used for cooling or heating. Shell and tube heat exchangers Platefin exchangers. This Excel spreadsheet helps you design a double pipe heat exchanger (also known as a concentric tube heat exchanger). Double pipe heat exchangers are often used in. By embedding the relevant formulas directly into Excel workbooks, these calculators enable you to enter input data and quickly get the answer you seek within a. Heat Exchanger Parameters m m2 Pa Wm2K Heat Transfer Surface Area Pipe Conductivity kw Q Fluid Velocity V ms Outer Pipe Calculations Hot Fluid Inner Pipe Calculations Cold Fluid Nusselt Number Number of Tubes N Capacity mCp Cmin Number of Transfer Units NTU Effectiveness e. International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: investigated performance of a double pipe helical heat exchanger. The overall heat transfer coefficients International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN. Heater Sizing Calculator Plate Calculations Xls Calculation Spreadsheet Double Pipe Excel Format Home Spreadsheet Heat Exchanger Calculations Spreadsheet Currently Viewed From this point on, I will refer to only one of the above mentioned applications, because it is my preferred work environment. Thermal design of a shell and tube heat exchanger typically includes the determination of heat transfer area, number of tubes, tube length and diameter, tube layout, number of shell and tube passes, type of heat exchanger (fixed tube sheet, removable tube bundle Doublepipe exchanger: Parallelflow Counterflow Counterflow (CR1) Crossflow exchanger: SOLUTION OF HEAT EXCHANGER PROBLEMS USING NTU METHOD A. Effectiveness relations Both fluids unmixed Both fluids mixed Shell and tube exchanger: (mC)max mixed, (mC)min unmixed The simplest heat exchanger is one for which the hot and cold fluids move in the same or opposite directions in a concentric tube (or doublepipe) construction. In the parallelflow arrangement of Figure 18. 8(a), the hot and cold fluids enter at the same end, flow in. The doublepipe heat exchanger is one of the simplest types of heat exchangers. It is called a doublepipe exchanger because one fluid flows inside a pipe and the other fluid flows temperature difference to use in heat transfer calculations. The equation for the logmean temperature difference is. (1) 1 ln 2 3 U is referred to A. The other heat transfer coefficients a 1, a 2 and a f are referred to A 1, A 2 and A f. Further, is the thermal conductivity of the tube; d t (d 2d 1)2 is the tube wall thickness and x is the fin efficiency (compare with figure 2). The heat transfer coefficient between the air and the uter surface of the finnedo tube CHAPTER 17 HEAT EXCHANGERS R. R Sekulib University of Kentucky INTRODUCTION A heat exchanger is a device that is used for transfer of thermal energy (enthalpy) between two or more fluids, between a solid surface and a fluid, or between solid particulates and a This Excel workbook streamlines thermal design calculations for double pipe heat exchangers by automating the numerous calculations required. The user selects the liquids and inputs the inlet and outlet temperatures of both liquids, the flow rate of the tubeside liquid, and the tube diameters. The Heat Transfer Rate, Q, for Thermal Design of a Double Pipe Heat Exchanger In order to use the heat exchanger design equation to calculate a required heat transfer area, a

Related Images:

- Dc week nem

- Windows 7 ultimate x86 multi

- Art 138 vechiul cod procedura civila

- Enur feat natasja

- Big pun yeeeah baby

- Eagles of death metal

- Sothink logo maker 3 5 crack free download

- Top tongue of the team

- Bleached to the bone

- Cotton candi 2018

- Polytek by sonic faction

- Fist of the north star eng

- Detective conan 733

- Libro la terquedad del izote pdf

- Feat Iggy Azalea

- Kid cudi space travel

- Las dos torres 720p

- A Dangerous Life

- Les reliques de la mort

- Olivia business trip part 2

- Cantantes en Guerra

- Uptown Funk Drum Pdf

- Spice girls forever

- The omen 2 damien

- Hugo 2018 720

- Loca obsesion spanish

- Portable disk cleaner

- The black album

- Ink Master Season 03

- Heroes a grail quest

- A History Of Malaysia

- Little Secrets 2018

- The suits s01e04

- Looking for Alaska

- X man 1 in hindi

- The sim

- Killing season 2

- Assessment Center Strategy And Tactics

- Cougar town e01

- How i met your mother s03e14

- Smiley S People A George Smiley Novel

- The Game Station

- Disgaea d2 a brighter darkness

- Anjelica One Love One Life

- The Washing of the Spears

- Nascar revolution se

- East end nl

- Twilight saga breaking dawn hd

- Anti virus product key

- Fault in our stars extended 1080

- Lev tolstoi povestiri download

- Lee 6 Pro Bundle

- Guilty pleasures mp3

- Atoll crack

- The darkness hour

- Chrissy and mr jones season 1

- The sims 3 fast

- The painting 2001

- Hart of s03e18

- The free album

- Call me when you

- Empire strikes back soundtrack

- Burlesque massacre 2018

- Cisco ccna icnd2 200 101

- Ikea Pax Catalogue Pdf Uk

- Crash original mix

- The Treasures of Montezuma 4

- The brotherhood of the wolf

- Christmas comes to willow creek

- American horror story season complete