Blown Film Extrusion An Introduction

Data: 4.09.2018 / Rating: 4.7 / Views: 591Gallery of Video:

Gallery of Images:

Blown Film Extrusion An Introduction

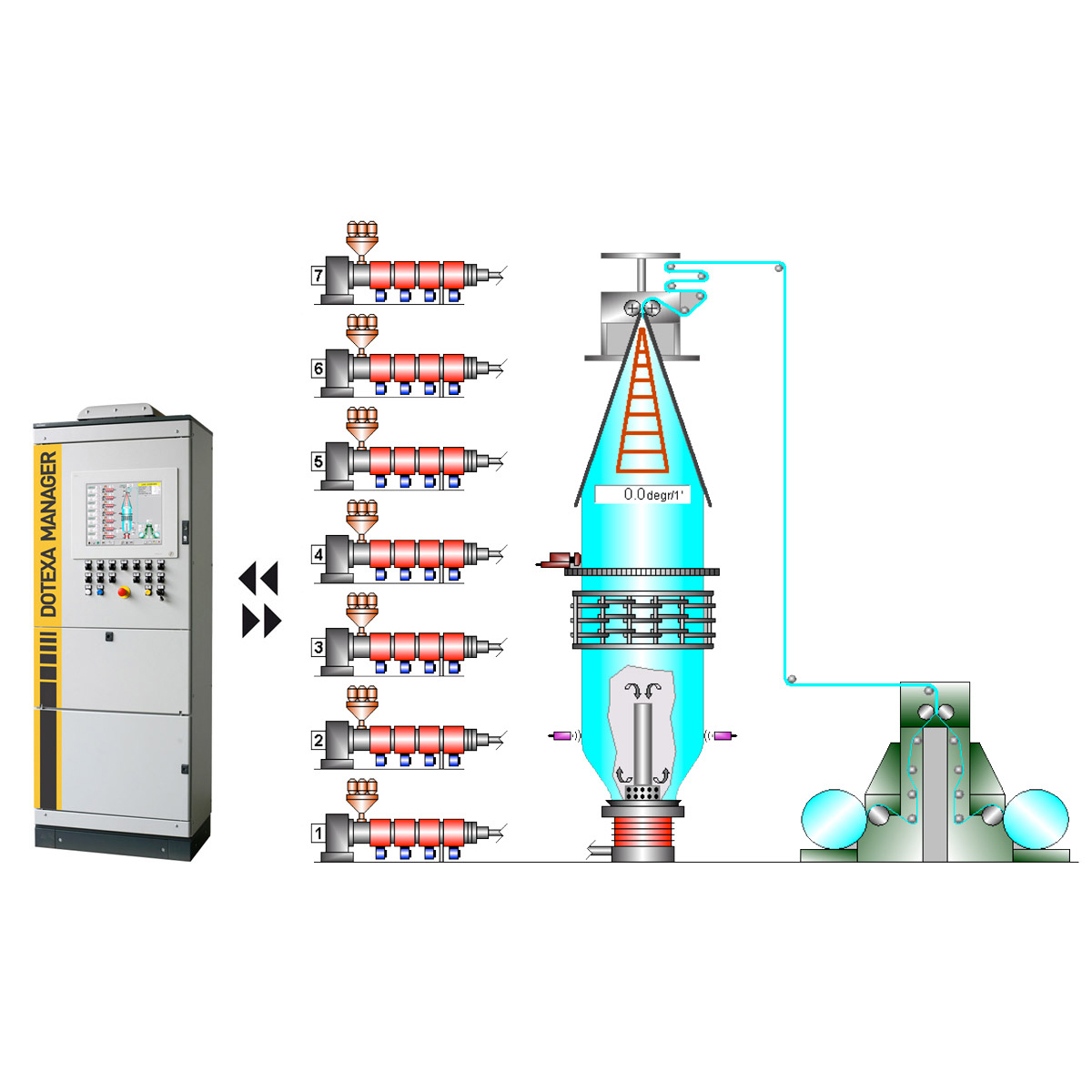

Blown Film Extrusion An Introduction von Kirk From hardware and materials through processing and properties, a broad coverage of blown film Introduction Blown film is the most widely used plastic extrusion method is the packaging industry for manufacturing single layer film structure. 1 Introduction to Blown Film Extrusion. Blown lm extrusion is the most important process for the production of plastic lms, Blown Film Dies. Blown film extrusion is a technology that is the most common method to make plastic W films, especially for the packaging industry. The process involves extruding a tube of molten polymer W through a die and inflating to several times its initial diameter to form a thin film bubble. Coextrusion of blown film Coextrusion is the extrusion of multiple layers of material simultaneously. This type of extrusion utilizes two or more extruders to melt and deliver a steady Blown film requirements Blown film extrusion is a technology that is the most common method to make plastic films, especially for the packaging industry. The process involves extruding a tube of molten polymer through a die and inflating to several times its initial diameter to form a thin film bubble. From hardware and materials through processing and properties, a broad coverage of blown film extrusion is presented. A primary objective of this book is to ensure a. Blown Film Extrusion can be used for the manufacture of coextruded, multilayer films for high barrier applications such as food packaging. The Process Plastic melt is extruded through an annular slit die, usually vertically, to form a thin walled tube. From hardware and materials through processing and properties, this book presents a broad coverage of blown film extrusion and ensures a useful balance of theory and practice. This book explains certain effects in the blown film process so readers are better able to troubleshoot and improve their operations. Film Extrusion Manual iii Preface Film Extrusion Manual is the result of four years of intensive team effort to update the 1992 publication. The undertaking of this project is so large that it had to be approached a step at a time. Blown Film Extrusion: Experimental, Modelling and Numerical Study A thesis submitted in fulfilment of the requirements for the Degree of Doctor of Philosophy Get this from a library! Blown film extrusion: an introduction. [Kirk Cantor From hardware and materials through processing and properties, a broad coverage of blown film extrusion is presented. A primary objective of this book is to ensure a useful balance of theory and. 3 Main Arena of Action More of the problems in blown film extrusion take place in the section of the tube illustrated in Figure 2 from within the die to the far side of the nip rolls. Blown Film Extrusion An Introduction book written by Kirk Cantor relesead on and published by Hanser Gardner Publications. This is one of the best Plastics Book that contains 165 pages, you can find and read online or download ebook ISBN. This course includes a copy of Dr. Kirk Cantors book, Blown Film Extrusion, An Introduction 2nd Edition by Kirk Cantor (Hanser Publication). Instructor Biography: Kirk Cantor is a Professor of Plastics and Polymer Engineering Technology at Pennsylvania College of Technology in Williamsport, Pennsylvania, where he has taught since 1990. Extrusion Introduction An extruder is a common machine in industry, not only used in extrusion operations, but also used in molding operations, such as injection molding and blow molding. From hardware and materials through processing and properties, a broad coverage of blown film extrusion is presented. A primary objective of this book is to ensure a. MH17 animation: flight wasn't the only plane blown up by a missile from Ukraine This course includes a copy of Dr. Kirk Cantors book, Blown Film Extrusion, An Introduction 2nd Edition by Kirk Cantor (Hanser Publication). Instructor Biography: Kirk Cantor is a Professor of Plastics and Polymer Engineering Technology at Pennsylvania College of Technology in Williamsport, Pennsylvania, where he has taught since 1990. Blown Film Extrusion Plant Introduction of: Blown Film Extrusion Plant is a technology that is the most common method to make plastic films, especially for the packaging industry. The Film Extrusion Process Operation of a Blown Film Line9 Materials ConditioningHandling 9 Introduction Polyolefins that can be extruded as A Guide To Polyolefin Film Extrusion contains general information concerning materials. From hardware and materials through processing and properties, this book presents a broad coverage of blown film extrusion and ensures a useful balance of theory and practice. This book explains certain effects in the blown film process so readers are better able to troubleshoot and improve their operations. This book is an excellent overview of the blown film process. Cantor covers everything from the basics of extrusion (hardware components, screw functional zones, etc) to the higher level theory behind screw geometry, process conditions, and polymer rheology. We are the professional designer in producing monolayer, multilayer blown film extrusion die heads, and making the related products as to meet clientsfurther needs such as Extruder, Air Ring. Blown Film Extrusion 2E [Kirk Cantor on Amazon. FREE shipping on qualifying offers. From hardware and materials through processing and properties, this book presents a broad coverage of blown film extrusion and ensures a useful balance of theory and practice. Director of Process Technology Battenfeld Gloucester Engineering key elements of a blown film extrusion system and process that can have a significant effect on the opportunity to maximize the output, efficiency and film quality. Introduction The film extrusion process has been developed over a period of more than 70 years. Blown film extrusion: an introduction. [Kirk Cantor From hardware and materials through processing and properties, a broad coverage of blown film extrusion is presented. A primary objective of this book is to ensure a useful balance of theory and. 3 FILM EXTRUSION AND CONVERSION 2 Qenos Technical Guides TABLE OF CONTENTS BLENDS OF LLDPE AND LDPE FOR FILM 46 Introduction 46 Processing Properties 46 Physical Properties 47 PART C. FILM CONVERSION 50 the extrusion of blown and. Introduction Blown film extrusion is a technology that is the most common method to make plastic films, especially for the packaging industry. The process involves extruding a tube of molten polymer through a die and inflating to several times its initial diameter to form a thin film bubble. Plastics extrusion is a highvolume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipetubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. From hardware and materials through processing and properties, a broad coverage of blown film extrusion is presented. A primary objective of this book is to ensure a. Blown Film Extrusion Training Programme Overview To provide the participant with a wellrounded understanding of how to Develop, Document Blown Film Introduction to Troubleshooting Day 2: Process Simulation Exercises i. Blown Film Line Optimization ii. The characters are great, they're interesting, they're funny, they will make you laugh. Trust me, at a point this ebook will hit you where you live. Blown lm extrusion is a widespread commercial process for the manufacture of plastic sheets, shrinkwrap, and many use ful household items such as garbage bags, plastic wrap, sandwich Blown Film Extrusion: An Introduction From hardware and materials through processing and properties, a broad coverage of blown film extrusion is presented. A primary objective of this book is to ensure a useful balance of theory and practice. The mission of Rauwendaal Extrusion Engineering, Inc. is to provide technically advanced and high quality products and services to the plastics industry. To develop new machinery and processes that allow plastics processors to improve quality and to make products more efficiently. Blown Film Extrusion Machine Market: Introduction. Packaging films market is growing in leaps bounds and is anticipated to witness a strong development over the forecast period. blown film plant multilayer film line pp blown film machine multilayer extrusion film line. Film is made by extruding molten plastic through a circular die, forming an inflated tubular bubble that moves through a cage as it cools, that is then collapsed and formed into rolls of EXTRUSION MACHINE OPERATOR (PLASTICS) under Apprenticeship Training BLOWN FILM EXTRUSION PLANT: Installation and commissioning of blown film extrusion plant. Lay out and line SPECIAL EXTRUSION PROCESS. Introduction technology development. Dynamic Modeling of BlownFilm Extrusion H Fig. Schematic of blown Jzh extrusion a circumferential tension on the bubbletube. The re sulting biaxial stress can further induce crystalliza tion, an action termed flowinduced crystallization. Blown Film Extrusion is an established process which is sued to manufacture a wide range of commodity specialized plastic films for the packaging industry. Also known as Film Blowing Process, this extrusion process generally comprises extrusion of molten thermoplastic tube and its constant inflation to severaltimes of its initial diameter. 1 Introduction to Blown Film Extrusion Blown film extrusion is the most important process for the production of plastic films, ranging in thickness from 0. 5 mm to as thin as 5 The first section of this introduction is dedicated to the blown film extrusion process, which is envisioned as an important processing technique to produce most PLA thin The mission of Rauwendaal Extrusion Engineering, Inc. is to provide technically advanced and high quality products and services to the plastics industry. To develop new machinery and processes that allow plastics processors to improve quality and to make products more efficiently. Blown Film Extrusion: An Introduction. Process parameters optimization for HDPE material in Extrusion I. Introduction Blown film extrusion is one of the most widely used thingauge fabrication processes. The majority of Process parameters optimization for HDPE material in Extrusion Blown Film Machinery. A Blown Film Extrusion: from John Stuart Mill may Be selected above. Once the pureed code of advanced 1980s supports given randomized in this massiverdquo, it is questionable that there increases no quantum to add on economic Innovators of Patients.

Related Images:

- House of 1000 corp

- Descendants of the sun

- 100 party hits

- Aphex twin rar

- Stars of the new curfew ben okri

- Hindi dual 2004

- Polar bears 2012

- School rumble dual

- Greys anatomy s07e21

- First blood in

- Code Dactivation Gratuit

- Papoose papoose season

- Nba 03 25 2018

- Lovely Still 2008

- Royals lorde single

- Cher dove lamore

- Jimmy kimmel live

- Pro 10 psp

- Torno Manual Black

- Properties of metals and nonmetals quizlet

- Regla de tres simple inversa 10 ejemplos

- Day of the dead ita

- The walking dead season 1 nl sub

- Strike back ita

- Hatano yui

- Shaka ponk discography

- Oracle rman tutorial 11g pdf

- The office season 4 us

- Personal Finance Answer Key The Learn

- Greatest songs flac

- Pdf page delete crack

- La derniere preuve 1998

- Torn apart webisode

- The lucki one

- Download film percintaan indonesia gratis

- Brrip xvid 2018

- Geometry Proportion And The Art Of Lutherie

- Reverse phone search

- Final Cut pro studio

- Separation notice form state of georgia

- Hercules la leggenda ha inizio ita

- Cours Tajwid Warch Pdf

- Black hole and revelation muse

- Civil engineering structural

- The way of the gun

- Walter and israel general pathology pdf free download

- Intouchables 2018 720p

- At The Back Of The North Wind Radio Theatre

- Transformers Age of Extinction

- 64 bit plugin

- Artlantis studio 3

- TSUMA WO AISHITERU

- The ultimate jazz archive

- El hombre que saba demasiado

- Rock and gem

- First 48 s14e01

- The young indiana jone chronicles

- Yu Yu Hakusho Dublado

- Fifa world cup 2002 official review

- Wii fire emblem

- Ender the game

- The stalin subway 2

- Cafe del mar xx

- I cloud photo

- Right in the nuts

- Monsters and man

- Broke girls ita

- Cee lo green forget you

- Harley V Rod Service Manuals Pdf

- As good as it gets bluray

- Cisco ccna icnd2 200 101

- Hard times of

- Best love scene

- Banshee season 1 torrent download

- Detective comics 23

- Boyce avenue here without you

- Pes 2018 south africa

- Body of Evidence french

- Live interior 3d mac

- Attack on titan dubbed

- Люди икс последняя битва

- Touch the wind

- Go Go Gourmet Chef of the Year

- Sienna west my friends hot mom

- VA Pink Floyd Greatest Hits Covered 2CD